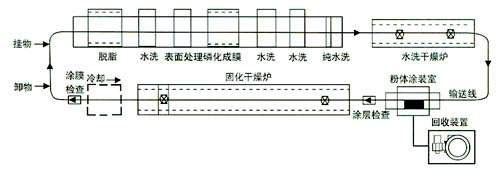

Pre - treatment manual simple process and automatic pre - treatment process, the latter is divided into automatic spray and automatic dip spray two processes. The workpiece must be surface treated to remove oil and rust before spraying. In this section used more liquid, mainly rust remover, degreasing agent, table adjustment, phosphating agent and so on.

In the processing section or workshop before the painting production line, attention should be paid to the establishment of the necessary purchase, transportation, storage and use of strong acid and alkali system, to provide workers with the necessary protective clothing, safe and reliable dressing, handling, configuration of appliances, as well as the development of emergency treatment measures and rescue measures in case of accidents. Secondly, in the pretreatment section of painting production line, due to the existence of a certain amount of waste gas, waste liquid and other three waste substances, so in terms of environmental protection measures, it is necessary to configure air exhaust, liquid discharge and three waste treatment devices.

The quality of the pre-treated workpiece should be different due to the different pretreatment solution and coating production line process. Better processing of the workpiece, surface oil, rust to do, in order to prevent a short period of time to rust again, generally should be in the pretreatment after several processes, phosphating or passivation treatment: before spraying powder, also should have phosphating workpiece for drying, to its surface moisture. Small batch single production, generally using natural air drying, sun drying, air drying. And for large quantities of flow work, generally take low temperature drying, using oven or drying road.

Spraying powder coating organization production

For small batch workpiece, manual dusting device is generally adopted, and for large batch workpiece, manual or automatic dusting device is generally used. Whether manual or automatic dusting, quality control is very important. To ensure that the spraying workpiece powder uniform, consistent thickness, to prevent thin spray, leakage spray, wipe off and other defects.

Coating production line in the process, but also should pay attention to the hook part of workpiece, before entering the curing, should adhere to its powder as far as possible will blow out, prevent excess powder curing of hook, some for curing remove residual powder before difficulties, should be timely stripping hook has solidified powder film, conductive to ensure the hook is good, and the number of artifacts to the powder.

Production management of curing process in coating line

This process should pay attention to: sprayed workpiece, if it is a small batch of single production, into the curing furnace before paying attention to prevent falling powder, such as powder rubbing phenomenon, should be timely spray powder. When baking, strict process and temperature, time control, pay attention to prevent color difference, over baking or too short time caused by insufficient curing.

For large quantities of automatic delivery of the workpiece, in the drying road before also carefully check whether leakage spray, spray thin or local powder phenomenon, such as found unqualified parts, should be closed to prevent entering the drying road, as far as possible to take down the spray. If individual workpiece is not qualified due to thin spray, it can be re-sprayed and solidified again after curing.

Post time: Jan-17-2022