Best Cyclone Dust Collector Factory – Whirlwind dust separator F-300 – Jinming

Best Cyclone Dust Collector Factory – Whirlwind dust separator F-300 – Jinming Detail:

Introduction

Cyclone dust collector is a kind of dust removal device. The dedusting mechanism is to make the dust-bearing air flow rotate, the dust particles are separated from the air flow by centrifugal force and collected on the wall of the device, and then the dust particles fall into the dust hopper by gravity. Each component of cyclone dust collector has a certain size proportion, and the change of each proportion relation can affect the efficiency and pressure loss of cyclone dust collector, among which the diameter of dust collector, the size of air inlet and the diameter of exhaust pipe are the main influencing factors. In use, it should be noted that advantages can also be turned into disadvantages when a certain threshold is exceeded. In addition, some factors are beneficial to improve the dust removal efficiency, but will increase the pressure loss, so the adjustment of each factor must be taken into account.

Cyclone dust collector began to be used in 1885 and has developed into many forms. According to the way of airflow entry, it can be divided into tangential entry type and axial entry type. Under the same pressure loss, the latter can handle about three times as much gas as the former, and the flow distribution is uniform.

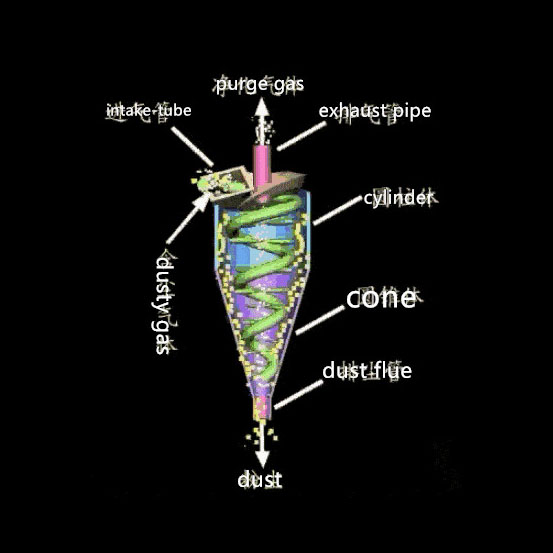

Cyclone dust collector is composed of an intake pipe, an exhaust pipe, a cylinder, a cone and a cinder hopper. Cyclone dust collector is simple in structure, easy to manufacture, installation and maintenance management, equipment investment and operating costs are low, has been widely used to separate solid and liquid particles from air flow, or from liquid solid particles. Under normal operating conditions, the centrifugal force acting on particles is 5 ~ 2500 times that of gravity, so the efficiency of cyclone dust collector is significantly higher than that of gravity settling chamber. Based on this principle, a dust removal efficiency of more than 90% cyclone dust removal device has been successfully studied. In the mechanical dust collector, the cyclone dust collector is a kind of high efficiency. It is suitable for the removal of non-viscous and non-fibrous dust, mostly used to remove more than 5μm particles, parallel multi-pipe cyclone dust collector device for 3μm particles also has 80 ~ 85% dust removal efficiency. The cyclone dust collector is made of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance. It can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. In terms of technology and economy, the pressure loss control range of cyclone dust collector is generally 500 ~ 2000Pa. Therefore, it belongs to the medium effect dust collector, and can be used for the purification of high temperature flue gas, is a widely used dust collector, mostly used in boiler flue gas dust removal, multi-stage dust removal and pre-dust removal. Its main disadvantage is its effect on fine dust particles. The removal efficiency of 5μm) was low.

Suitable for all kinds of industrial dust control

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Best Cyclone Dust Collector Factory – Whirlwind dust separator F-300 – Jinming , The product will supply to all over the world, such as: Ghana, Kenya, Greenland, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.