High Quality Router Dust Collection Factories – Activated carbon adsorption, desorption, catalytic combustion – Jinming

High Quality Router Dust Collection Factories – Activated carbon adsorption, desorption, catalytic combustion – Jinming Detail:

Introduction

Workshop is engaged in the production operation will poduce the harmful gas such as stimulation of pollutants, to nature ecology and plant environmental hazards can cause air pollution, waste gas emissions from the equipment will be collected, the use of activated carbon adsorption tower will be treated as waste gas to the air pollutant emission standards before discharge into the atmosphere, so as not to ause the harm of environment and staff.

Activated carbon absorption, stripping, catalytic combustion is one of my company a new generation of VOCs processing equipment, is the element of adsorptive enrichment and thermal oxidation unit a organically, mainly is suitable for the low concentration organic gases and should not be used directly or catalytic combustion method and adsorption method of recycling treatment of organic waste gas, especially for large volume processing, Satisfactory economic and social effects can be obtained. After adsorption, purification and desistation, it is converted into organic waste gas with small air volume and high concentration, which is treated by thermal oxidation, and the heat released by the combustion of organic matter is utilized.

Technical characteristics of activated carbon adsorption and desorption catalytic combustion device

1. Adsorption purification, stable treatment effect, to ensure that the exhaust gas discharge standards.

2. With manual and automatic desorption function, the choice of precious metal catalyst, through catalytic combustion reaction will be organic matter conversion, catalytic.

3. Adopt PLC control, supporting can operate touch screen, easy to operate, simple maintenance and management.

4. With multiple measures, the main reactor is equipped with explosion relief device, set up multi-point temperature detection, with fault alarm and emergency treatment ability.

Suitable for all kinds of industrial waste gas treatment

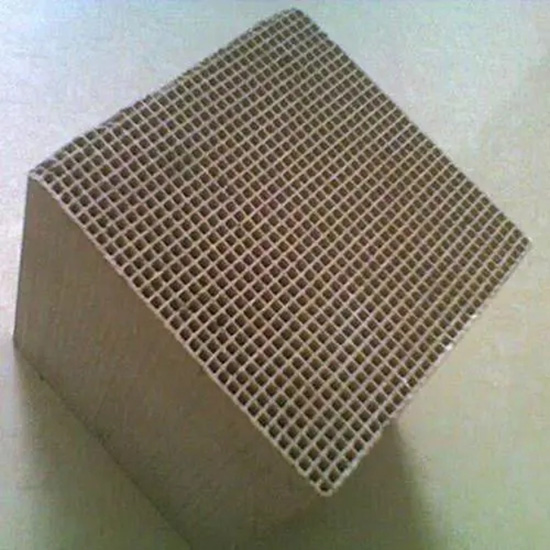

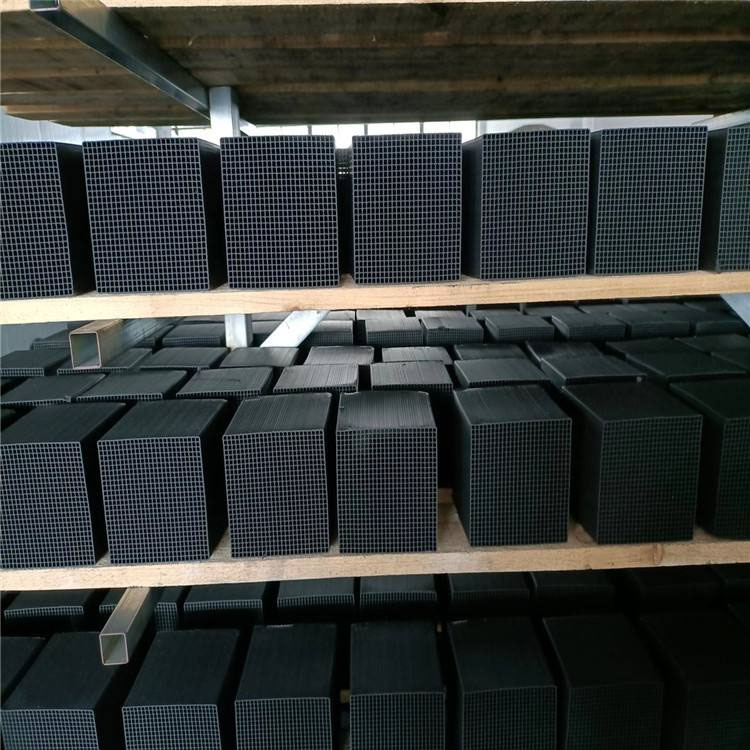

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for High Quality Router Dust Collection Factories – Activated carbon adsorption, desorption, catalytic combustion – Jinming , The product will supply to all over the world, such as: Mauritius, panama, Eindhoven, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.