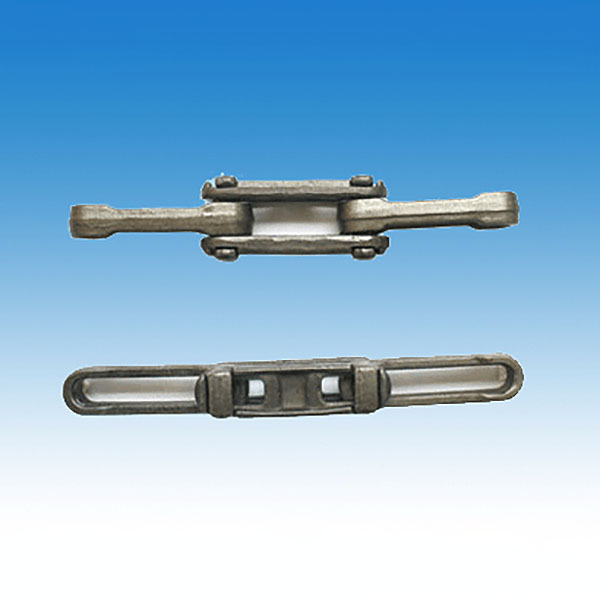

Ground type heavy duty conveyor plate chainSS-6000

The characteristics of

Ground chain structure is very simple, only a chain plate with hinged rings on both sides and a pin. One side of both hinge rings is fixedly connected with the pin shaft and is called a fixed hinge ring. The other side is in the inside of the hinge ring and the pin shaft rolling connection, called the active hinge ring. The movable hinge ring and pin form the hinge of the flat-top chain. Because the flat top chain is often used to contact with liquid substances, so the chain plate material is mostly made of stainless steel, of course, but also useful engineering plastics to manufacture. The hinge ring of steel flat-top chain is rolled, so the hinge ring is slotted and roundness is not easy to ensure. It pulls apart under heavy loads. It's a weak link. With the development of tooling plastics, engineering plastics flat-top chain has also been developed. Because the flat top chain plate of engineering plastics is cast, the structure of the chain plate can be more complex as required. Because there are reinforcing ribs on the chain plate, it can improve the strength of the chain. The strength of the double-bend stiffened ribbed straight flat top chain is not lower than that of the steel plain hinged flat top chain.

Application

The ground chain has the advantages of simple structure, light weight, easy manufacturing and maintenance. The top plate of the flat-top chain provides a horizontal bearing surface of a certain width for conveying materials. The roof width is determined according to the requirements of conveying materials. When the chain meshes with the sprocket, the hinge ring itself is the part meshing with the sprocket. Because of the small clearance on both sides of the parallel roof chain, it can only be moved in a straight line. It is very important to determine the fitting when using a flat-top chain. It is widely used in the design of straight line chain conveyor. A number of parallel chain conveyor can be used to replace the net belt conveyor.

Plate chain conveyor is suitable for heavy duty transport of irregularly shaped articles. The chain adopts hollow large roller chain with attachment, and the attachment of synchronous chain on both sides is connected with plate member to form continuous flat plate in the conveying direction, so that the operation is stable. This machine can be used with chain conveyor or roller conveyor to achieve rotary transmission.

The material

Carbon steel, stainless steel, thermoplastic chain, according to the needs of the product can choose different width, different shapes of the roof to complete the straight line, turning, lifting and other requirements.

Classification

Because of the different control methods, it can be divided into continuous operation and intermittent operation.

Used for all kinds of workpiece painting, other models can be customized.